Fasteners are integral components in various construction and manufacturing projects, serving the critical function of joining materials together securely. These versatile tools come in numerous types, each designed for specific applications, ranging from simple screws and bolts to advanced industrial fasteners. Understanding the different types of fasteners and their applications is essential for achieving optimal results in any project. Additionally, fasteners often interact with other materials, such as geotextiles, to enhance stability and durability in construction.

What are the different types of fasteners?

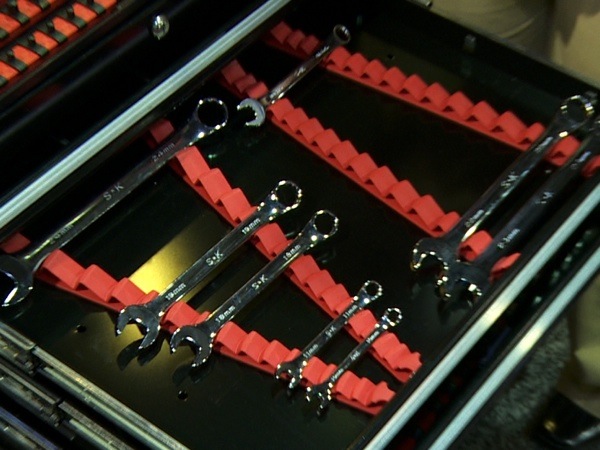

Fasteners come in various types, including screws, bolts, nuts, washers, rivets, and anchors. Each type serves a specific purpose:

- Screws: Used for general fastening, they come in different head styles and thread types.

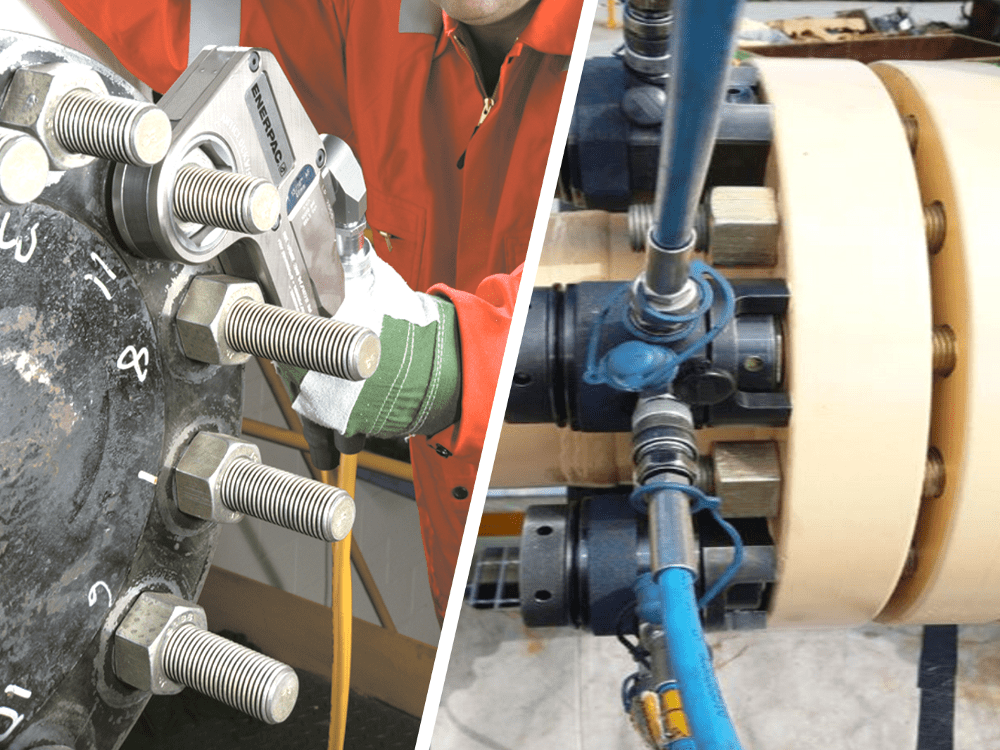

- Bolts: Typically paired with nuts, bolts are used for heavy-duty applications.

- Nuts: Designed to pair with bolts to secure materials.

- Washers: Provide a smooth surface and distribute load evenly.

- Rivets: Permanent fasteners used in metalworking and aerospace.

- Anchors: Used to secure objects to concrete or masonry surfaces.

How do fasteners impact construction projects?

Fasteners play a crucial role in the construction industry by providing structural integrity and stability. They ensure that materials such as wood, metal, and concrete are securely joined, which is essential for building durability and safety. For instance, fasteners are used to assemble frameworks, secure fixtures, and support load-bearing structures. Proper selection and application of fasteners can significantly affect the longevity and performance of a construction project.

What is the importance of choosing the right fastener for a project?

Choosing the right fastener is vital for ensuring the effectiveness and safety of a project. The wrong fastener can lead to structural failures, increased maintenance, and potential hazards. Factors to consider include the material being fastened, the load-bearing requirements, environmental conditions, and the type of stress the fastener will experience. For example, fasteners used in outdoor environments must be resistant to corrosion. In certain applications, fasteners may need to work in conjunction with materials like geotextiles to enhance performance and stability.

How do fasteners interact with geotextiles in construction?

Geotextiles are synthetic fabrics used in construction to improve soil stability, drainage, and erosion control. Fasteners play a critical role in securing geotextiles in place, ensuring they function effectively. For instance, in road construction, fasteners can be used to anchor geotextiles to the soil, providing additional reinforcement to prevent erosion and support the weight of the road surface. The proper integration of fasteners with geotextiles enhances the overall stability and performance of construction projects.

Fasteners are indispensable tools in construction and manufacturing, offering a range of options to suit various applications. From screws and bolts to rivets and anchors, each type of fastener serves a specific purpose and contributes to the structural integrity of projects. Selecting the appropriate fastener is crucial for achieving optimal performance and safety. Additionally, fasteners often work in tandem with materials like geotextiles to enhance stability and durability. Understanding the different types of fasteners and their applications ensures successful project outcomes and long-lasting results.