When it comes to selecting the right Netzsch onderdelen (parts) for your machinery, the process can seem daunting. With various options available, understanding your specific requirements is essential. This article will guide you through the key considerations to help you make an informed decision.

Understand Your Application

Before diving into the selection process, it’s crucial to understand the application for which you need the Netzsch onderdelen. Different industries and processes have unique demands, so consider the following factors:

- Type of Material: What materials will your machinery handle? Netzsch parts are designed for specific applications, so knowing the type of material is essential.

- Operating Conditions: Consider temperature, pressure, and any chemical exposure. The right parts must withstand these conditions to ensure longevity and efficiency.

Research Available Options

Once you have a clear understanding of your application, it’s time to research the available Netzsch onderdelen. Here are some common types:

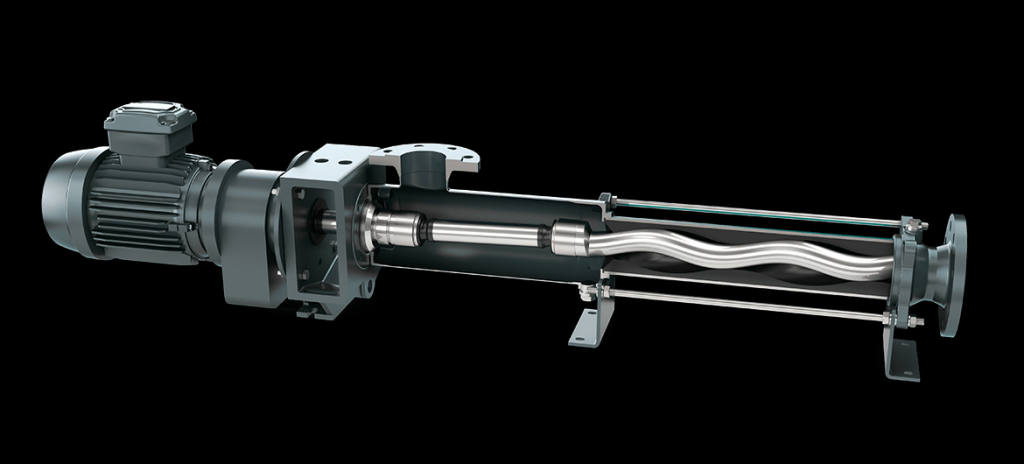

- Pumps: Ensure the pump is suitable for the type of material and flow rate you require.

- Mixers: Look for mixers that can handle the viscosity and volume of your materials.

- Valves: Choose valves that provide the necessary precision and control for your processes.

Quality and Compatibility

Quality should never be compromised when selecting Netzsch onderdelen. Here are some tips to ensure you choose high-quality and compatible parts:

- Manufacturer Reputation: Opt for parts from reputable manufacturers known for their quality and reliability.

- Compatibility: Ensure that the parts are compatible with your existing machinery. Mismatched components can lead to inefficiencies and potential damage.

Consult with Experts

Don’t hesitate to seek advice from experts in the field. They can provide valuable insights and recommendations based on their experience. Consider the following:

- Technical Support: Reach out to technical support teams who can help you understand which parts are best suited for your needs.

- Industry Forums: Engage in industry forums or discussions where you can ask questions and share experiences with others facing similar challenges.

Evaluate Costs and Budget

While quality is paramount, cost is also a significant factor. Evaluate your budget and consider the following:

- Initial Costs vs. Long-Term Savings: Sometimes, investing in higher-quality parts can lead to savings in maintenance and replacement costs over time.

- Warranty and Support: Check if the parts come with a warranty or support services, as this can add value to your purchase.

Conclusion

Choosing the right Netzsch onderdelen is a critical step in ensuring the efficiency and longevity of your machinery. By understanding your application, researching options, prioritizing quality, consulting with experts, and evaluating costs, you can make an informed decision that meets your specific needs. Remember, the right parts not only enhance performance but also contribute to the overall success of your operations.