In the complex world of construction and environmental management, strategic rigging practices are essential for the effective installation of geosynthetic lining systems. This article aims to provide a comprehensive guide on the importance of rigging, the challenges it faces, and the strategic approaches necessary for successful implementation. By dissecting the process of rigging, the guide highlights its critical role in enhancing the effectiveness and durability of geosynthetic lining systems.

Understanding Rigging’s Role in Geosynthetic Lining Projects

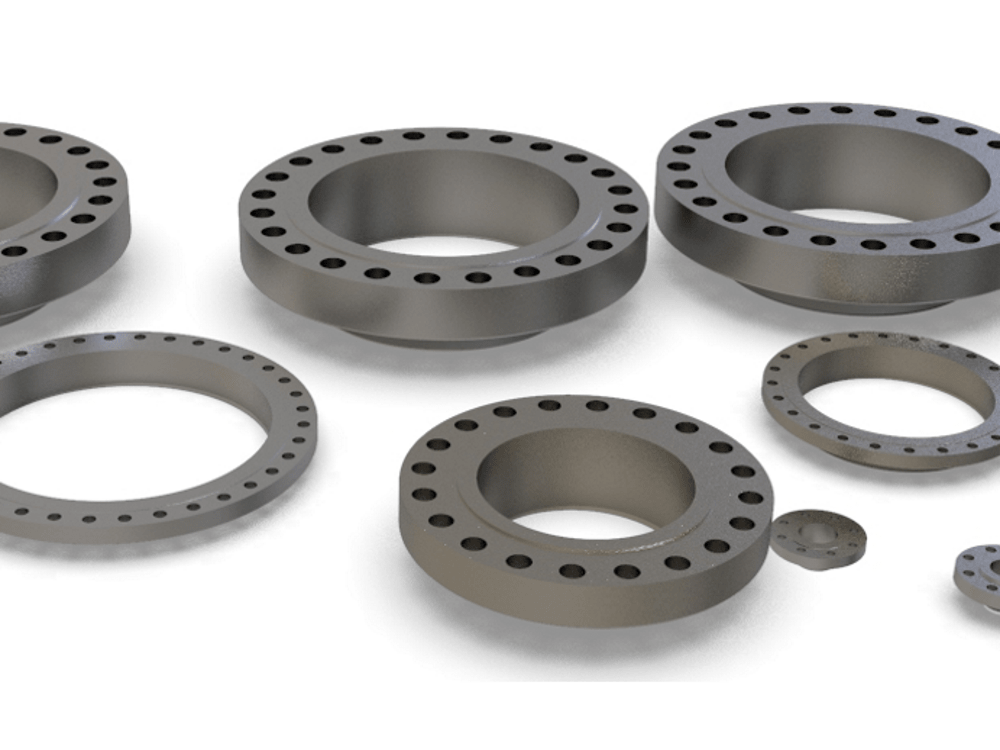

Rigging, within the scope of geosynthetic lining installations, encompasses the meticulous handling and positioning of materials such as geomembranes and geotextiles. This detailed process is vital for the materials’ safe and correct installation, which is crucial for their functionality and structural integrity.

The Significance of Rigging for Project Efficiency and Safety

The influence of rigging on the outcome of geosynthetic lining projects is profound, affecting the efficiency of installation, the safety of the workforce, and the ultimate success of the project. Implementing precise rigging methods is crucial for minimizing damage to materials, a factor critical for the system’s effectiveness in environmental and containment applications. Furthermore, optimized rigging practices can lead to significant reductions in project timelines and costs.

Navigating Rigging Challenges in Geosynthetic Installations

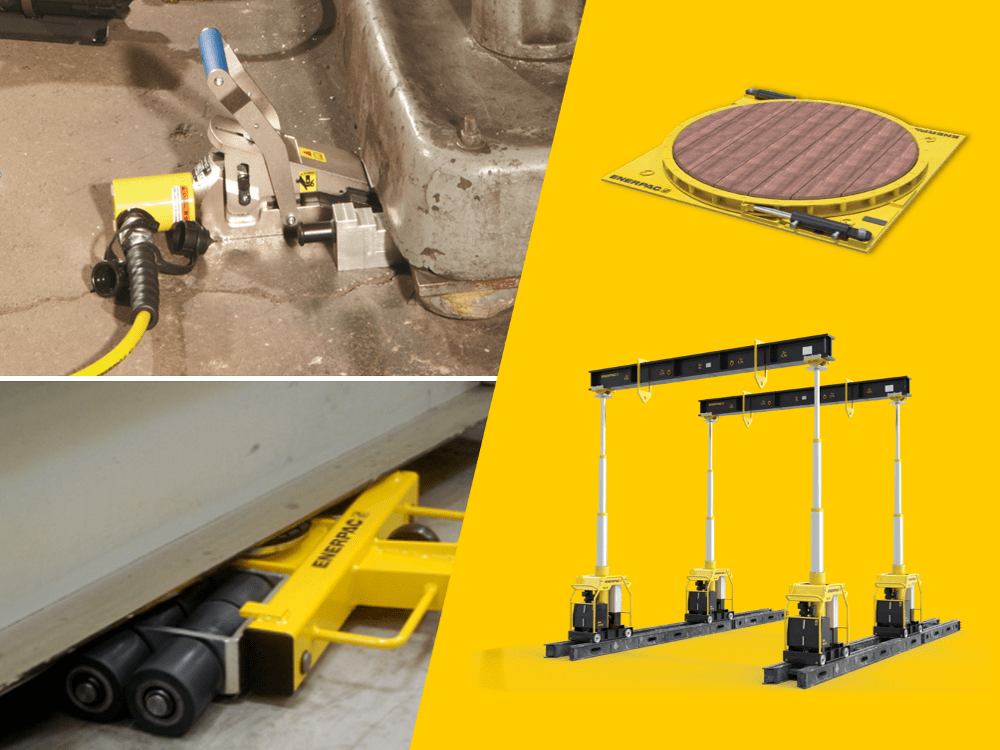

The rigging of geosynthetic materials presents unique challenges, including the potential for material damage and the impact of environmental conditions. Addressing these challenges requires the expertise of skilled rigging professionals, the utilization of advanced equipment, and detailed pre-installation planning. Such measures are instrumental in proactively identifying and addressing potential issues, ensuring a smooth and efficient installation process.

Rigging plays an essential role in the successful deployment of geosynthetic lining systems, with a significant impact on their efficiency and longevity. Through the deployment of experienced personnel, the application of specialized equipment, and thorough planning, the construction and environmental industries can achieve superior outcomes. With continuous advancements in rigging techniques and technologies, the future of geosynthetic lining installations is set to witness even further improvements.