In the realm of fluid transfer technology, the stainless steel progressive cavity pump stands out for its unique design and functionality. This guide explores its features, applications, advantages, and maintenance practices, making it an invaluable resource for anyone looking to understand this essential equipment.

What is a Stainless Steel Progressive Cavity Pump?

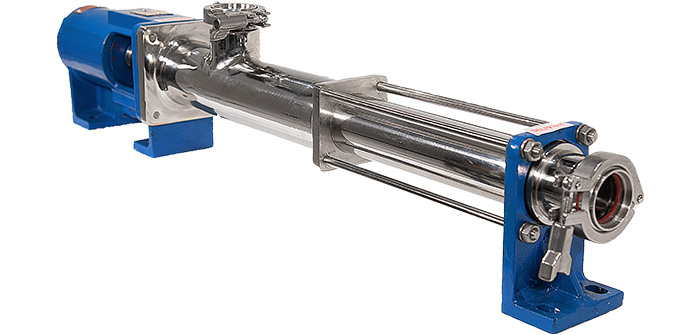

A stainless steel progressive cavity pump is a type of positive displacement pump that uses a helical rotor to move fluids through a stator. This design allows for the smooth and continuous flow of various types of fluids, including thick, viscous, and abrasive materials. The stainless steel construction enhances durability and corrosion resistance, making it suitable for a wide range of industrial applications.

Key Features

- Durable Construction: The stainless steel material offers excellent resistance to corrosion and wear, ensuring longevity and reliability in harsh environments.

- Smooth Operation: The helical rotor design minimizes pulsation, providing a steady flow rate and reducing the risk of cavitation.

- Versatility: Capable of handling different fluid types, including slurries, chemicals, and food products, making it ideal for diverse industries.

- Self-Priming Ability: This pump can handle air and is capable of self-priming, allowing for easier installation and operation.

Applications

The stainless steel progressive cavity pump is widely used across various industries due to its adaptability. Some common applications include:

- Food and Beverage Industry: Ideal for transferring viscous food products, sauces, and even dairy.

- Chemical Processing: Efficiently handles corrosive and abrasive chemicals, ensuring safe and effective transfer.

- Wastewater Management: Used in the treatment and transfer of sludge and other waste materials.

- Pharmaceuticals: Ensures hygienic transfer of sensitive fluids while maintaining strict sanitary standards.

Advantages

When considering a stainless steel progressive cavity pump, several advantages come to light:

- High Efficiency: The design allows for consistent flow rates, reducing energy consumption and operational costs.

- Low Maintenance: Fewer moving parts mean less wear and tear, resulting in lower maintenance requirements and downtime.

- Adaptability: Capable of handling various flow rates and pressures, making it suitable for different operational needs.

- Hygienic Design: The smooth surfaces and easy disassembly facilitate thorough cleaning, essential for food and pharmaceutical applications.

Maintenance Tips

To ensure the longevity and efficiency of your stainless steel progressive cavity pump, consider the following maintenance practices:

- Regular Inspections: Check for wear and tear, especially on the rotor and stator, to catch issues early.

- Proper Lubrication: Ensure that all moving parts are adequately lubricated to reduce friction and wear.

- Clean Regularly: Maintain cleanliness to prevent contamination, especially in food and pharmaceutical applications.

- Monitor Performance: Keep an eye on flow rates and pressure to detect any changes that may indicate potential problems.

Conclusion

The stainless steel progressive cavity pump is an essential tool in various industries, offering durability, efficiency, and versatility. By understanding its features, applications, advantages, and maintenance practices, users can maximize the potential of this remarkable pumping technology. Whether you are involved in food processing, chemical handling, or wastewater management, this pump can be a reliable asset in your operations.