Rivet guns, or riveters, are essential tools across various industries, providing a reliable method for securely fastening materials. Whether you’re a DIY enthusiast or a professional in construction, automotive, or manufacturing, exploring the world of rivet guns can significantly enhance your project outcomes. In this article, we’ll delve into the versatility of rivet guns, answer common questions, and explore their applications, with a particular focus on their role in geotextile materials.

What characterizes a rivet gun, and how does it operate?

A rivet gun is a specialized tool designed for fastening materials by driving rivets into place. Its operation involves pulling a metal mandrel through the hollow rivet, creating a secure and tight connection between two or more materials. Equipped with a trigger mechanism, the gun allows precise control over the force applied to the rivet.

What varieties of rivet guns are available?

Various types of rivet guns cater to specific needs. From handheld manual riveters to pneumatic rivet guns powered by compressed air and electric rivet guns for intricate projects – the options are diverse. The choice depends on factors such as material type, project scale, and the desired level of precision.

What are the primary applications of rivet guns?

Rivet guns find applications across a spectrum of industries. In construction, they secure metal sheets, beams, and panels. In automotive manufacturing, rivet guns play a crucial role in fastening components like body panels and frames. Their significance extends to aerospace, shipbuilding, and even DIY projects. The adaptability of rivet guns makes them indispensable for creating reliable and durable material connections.

How does geotextile tie into rivet guns?

Geotextile materials, commonly used in civil engineering and construction, aim to enhance soil stability and control erosion. Rivet guns can effectively fasten geotextile layers, creating a robust barrier against soil erosion. This application ensures the steadfast placement of geotextile materials, even in challenging environmental conditions.

Rivet guns emerge as powerful tools integral to diverse industries, providing a reliable solution for material fastening. Whether you’re engaged in a construction project or a DIY endeavor at home, a comprehensive understanding of rivet guns and their applications is vital for optimal results. The integration of rivet guns in geotextile applications underscores their versatility in tackling a range of engineering challenges. Consider the role of rivet guns as you embark on your next project for creating robust and enduring connections.

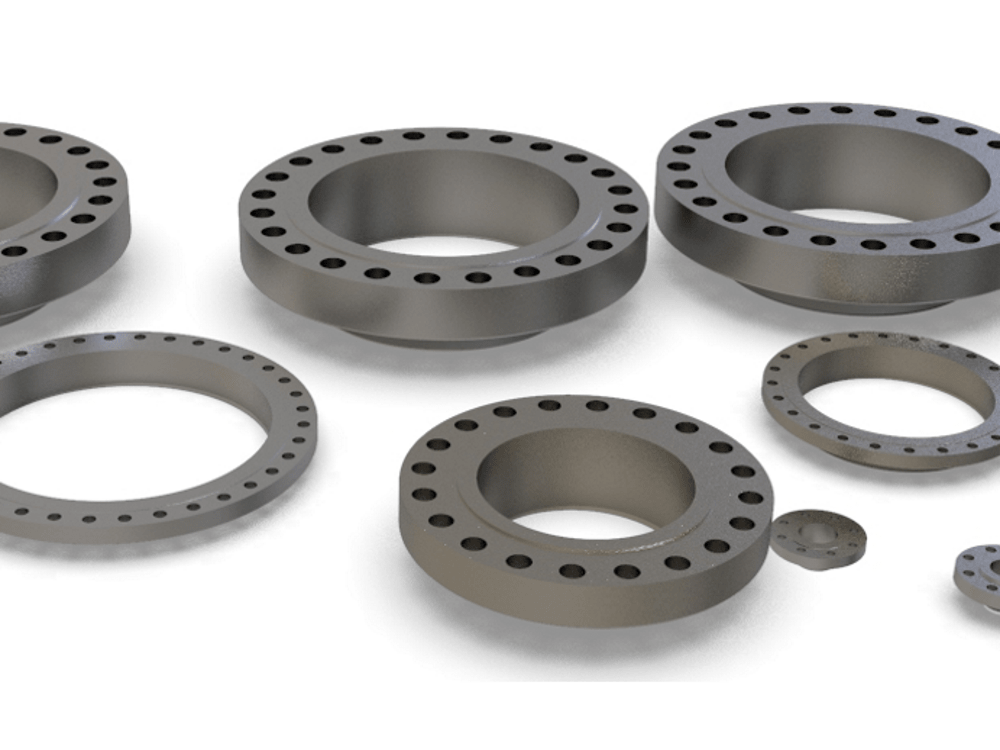

A217 Material is a type of high-grade alloy known for its exceptional strength, corrosion resistance, and high-temperature properties. This material is commonly used in demanding industrial applications where durability and performance are critical. A217 Material is often utilized in components such as valves, fittings, and pump parts that operate in harsh environments with corrosive fluids or extreme temperatures. Its excellent mechanical properties and resistance to wear make it an ideal choice for applications in industries such as oil and gas, chemical processing, and power generation. The reliability and longevity of A217 Material contribute to the efficient and safe operation of equipment in challenging operating conditions.